SHAVE MONTHS OFF

YOUR CONSTRUCTION CYCLE

Using steel provides cost effective, sustainable and efficient design solutions

MAXIMIZE YOUR RETURN ON INVESTMENT

Since there are no height or floor size restrictions when building with steel, builders can maximize the number of floors / units to be built or to be added onto a footprint. Steel buildings also retain their value for a longer period of time and save you a ton of money down the road!

SHORTER CONSTRUCTION CYCLES

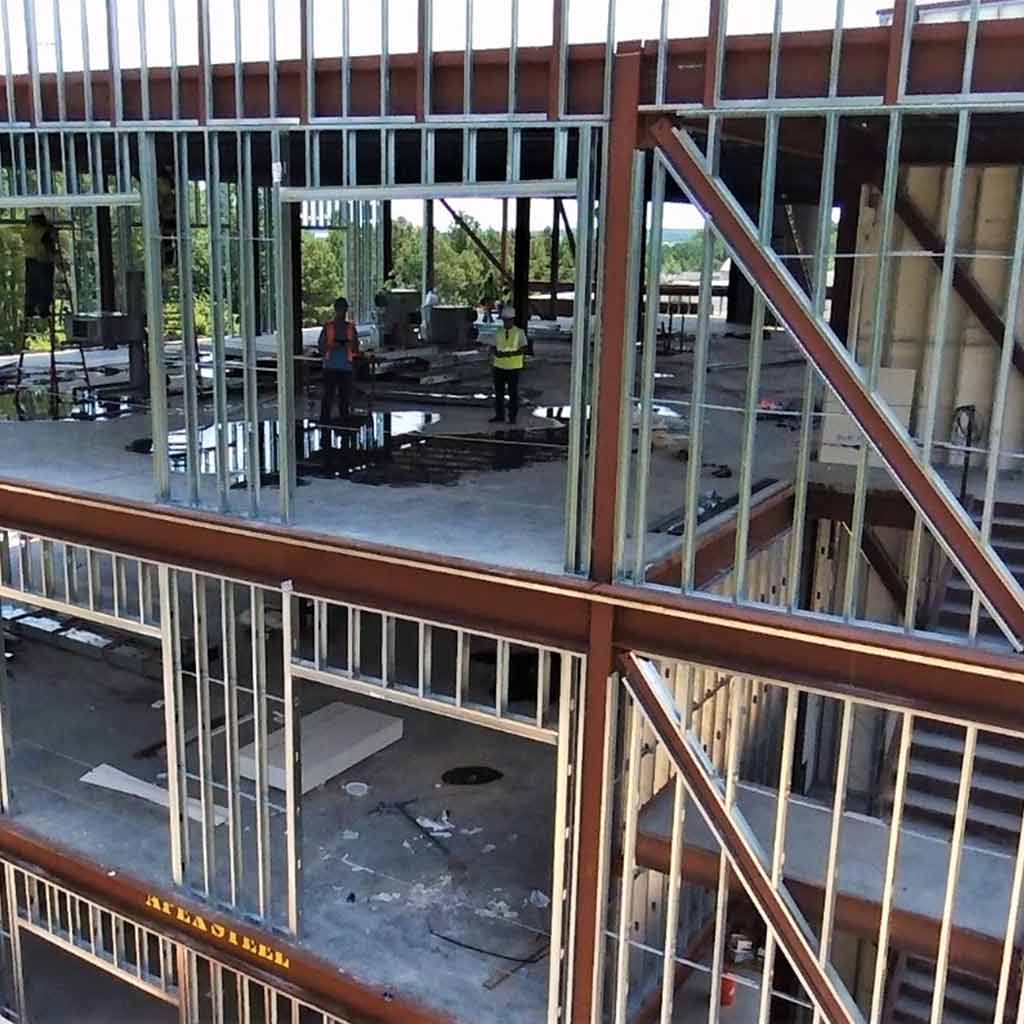

Buildings framed with cold-formed steel (CFS) can go up much faster than traditional materials like wood, concrete and masonry. Interior and Exterior wall panels come pre-built, delivered on site and ready for tilt up construction. Save yourself the hassle of worrying about time and materials, just use Crowder Steel Framing!

INCREASED DURABILITY

20x stronger than wood, sustainable, energy-efficient, providing big energy savings, mold-resistant, fire-resistant, able to withstand up to 2x hurricane-force winds, offering reduced insurance rates, low maintenance, fewer foundation problems over time, and higher resale value, just to name a few.

About us

Crowder Steel Framing

Our cold-formed steel is fabricated to its precise specifications by our team of engineers and steel fabricators. Our team has been developing and building residential and commercial projects since 1996.

When it comes to understanding the quality of product you deserve, we deliver! Once fabrication is complete, the cold-formed steel is transported to the construction site, where it can be erected and installed quickly.

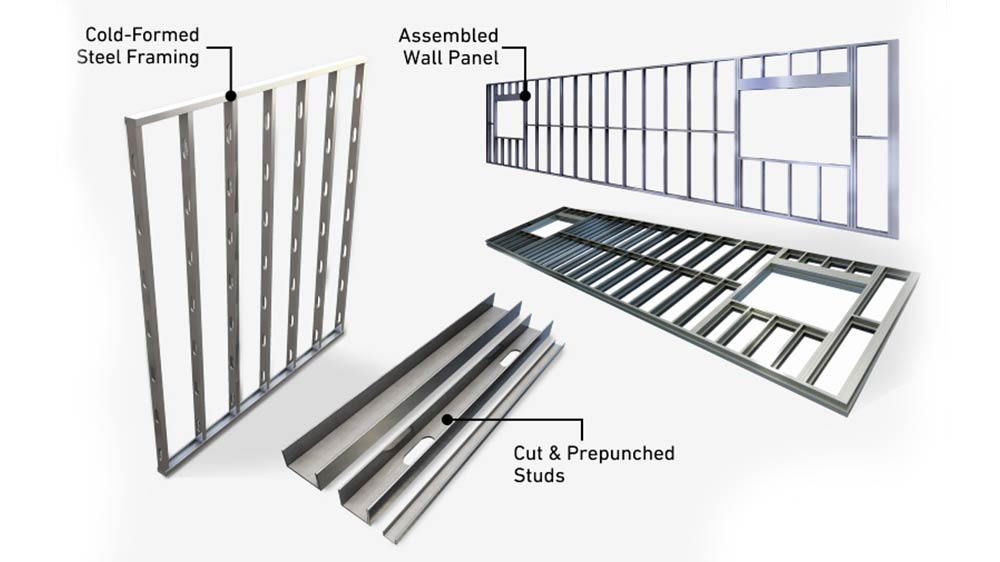

Cold-Formed Steel

Cold-formed steel has been used in framing since approximately 1850. Cold-formed steel (CFS) has all the benefits of steel plus several advantages for contractors and labor.

Cold-formed steel members are made from structural quality sheet steel formed into C-shaped sections and other shapes by rolling the steel through a series of dies without heating. The process is similar to forcing Play-Doh® through a forming tool that creates stars and other shapes.

Purlins, girts, zee’s, eave struts, angles, channels, hat sections and more are metal framing components created with cold-formed steel. It can be formed into multiple thicknesses for various structural and non-structural applications.

Comprehensive provisions for steel can be found in the International Building Codes, which adopted the American Iron and Steel Institute’s North American Standards for Cold-Formed Steel Framing. CFS has become increasingly popular for low to mid-rise frames over the decades. Cold-formed steel has numerous benefits for building construction and maintenance.

Metal reacts predictably under different stressors and loads, enabling engineers to make precise determinations about various load factors and required thicknesses of steel.

The foundation building framed in CFS will cost less than for a heavier frame such as wood because it has less weight to hold. CFS is also ideal for soil conditions that would ordinarily limit a structure’s size and weight.

Because cold-formed steel is created under stringent factory conditions, the material is remarkably consistent with a high degree of precision in its manufacture. This precision and consistency translate into less cutting on-site and little to no scrap to haul off.

Once a building project is complete, nobody will be able to see the members holding it erect, but you will know they are made of the strongest, most durable construction material on the market.

Benefits

Cost-Effective

Lower insurance rates and shorter project cycles.

STRENGTH

Steel will not warp, split, crack, or creep when exposed to the elements.

QUICKER INSTALLATION

We manufacture off-site in a controlled environment and install in half the time, Guaranteed.

Lower Maintenance

Unlike wood, steel is inorganic and does not contain moisture making it a termite/mold/rot-proof solution.

Sustainable

Steel is sustainable and is the most recycled material on Earth. 65 million tons of steel are recycled annually.

Customization

CFS can be customized to fit the specifications and safety requirements of any project.

Non-combustible

Steel framing is non-combustible. Which helps with building fire rating and safety.

Cheaper than concrete and better than wood, prefabricated CFS framing ensures that your building is enclosed faster, safer, and on budget.

For Developers

BUILT TO LAST

The resistance of Cold-Formed Steel to corrosion, mold, fire, high winds, and vermin, along with its structural stability, contributes to its longevity, a quality few other building materials can match.

SAVE MONEY ON MATERIALS

Connect with us so we can learn more about your project or send us your building plans. We can convert your building plans from wood to Cold-Formed Steel.

UNLIMITED DESIGN FLEXIBILITY

Our Cold-Formed Steel structures can range from single-family homes, warehouses, sheds, tiny homes, and more. Because our cold-formed steel is fabricated to exact standards, it provides unmatched precision and can be molded into just about any shape.

Our Approach

CALL US

Connect with us so we can learn more about your project or send us your building plans. We can convert your building plans from wood to Cold-Formed Steel.

ENGINEERED SOLUTIONS

Precision engineering, down to the millimeter: that’s what Cold-Formed Steel offers. Our experienced team can provide the most efficient designs.

ROI

Experience more efficiency and cost savings on projects with labor and supplies while putting more revenue back into your company.

design of cold-formed steel structures

Cold-Formed Steel Pros Is A Design-Led Process, Meaning That The Need For Skill To Construct The Building Is More In The Design Stage Rather Than On-Site. Stratus Steel System Uses The FRAMECAD Software Suite Which Integrates Design, Engineering Calculations, Structural Analysis, Detailing, And Roll Forming Machine Control. Providing Extreme Accuracy And Efficiencies In The Construction Process, Reducing Costs Of Engineering, Design, Waste, And Labor.

Our Products

- All

- WALL PANELS

- TRUSSES

- JOIST

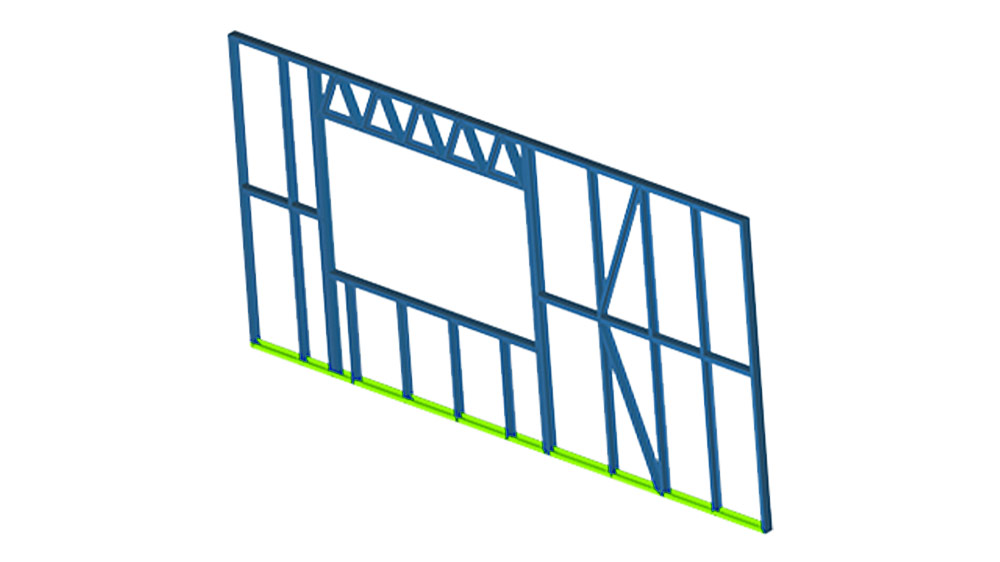

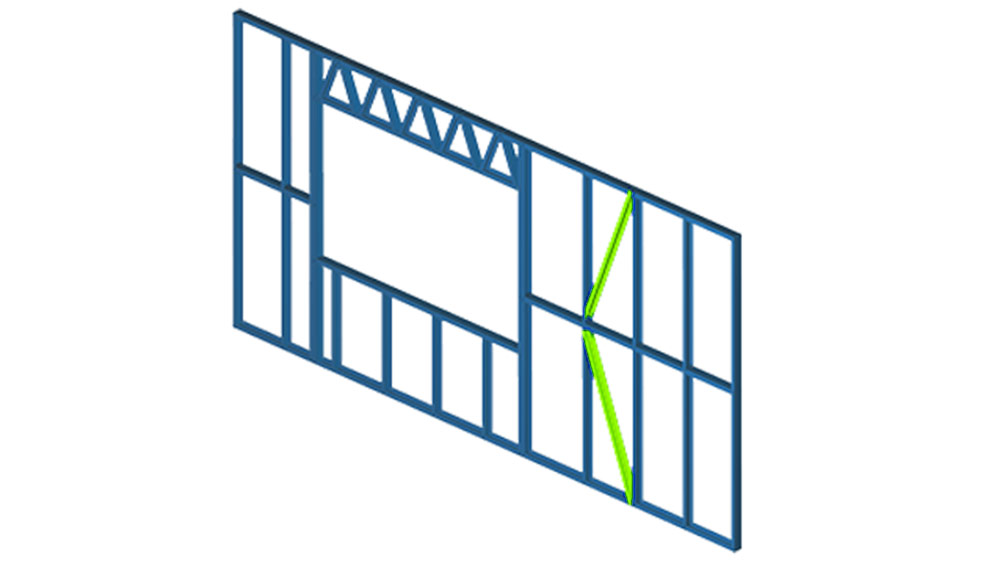

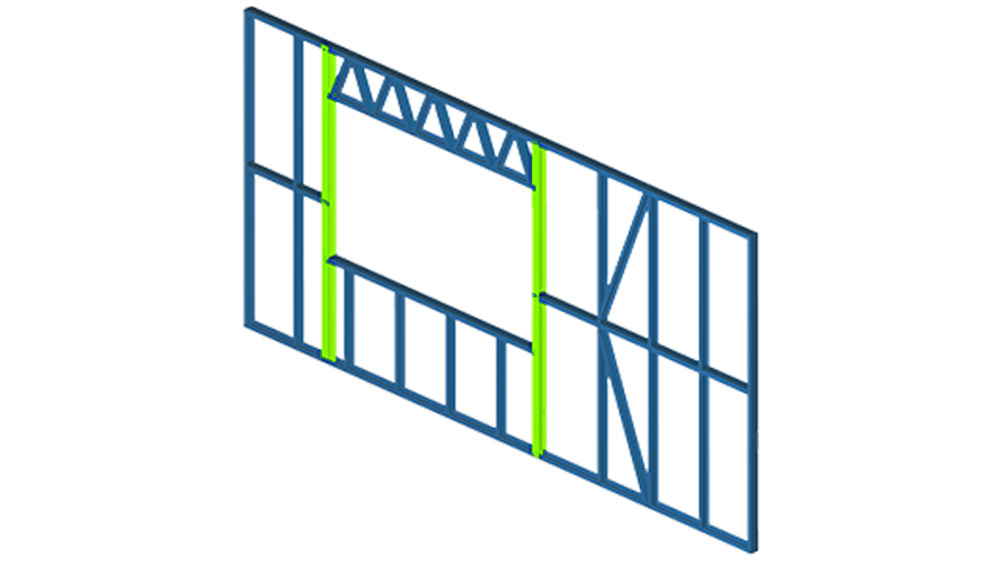

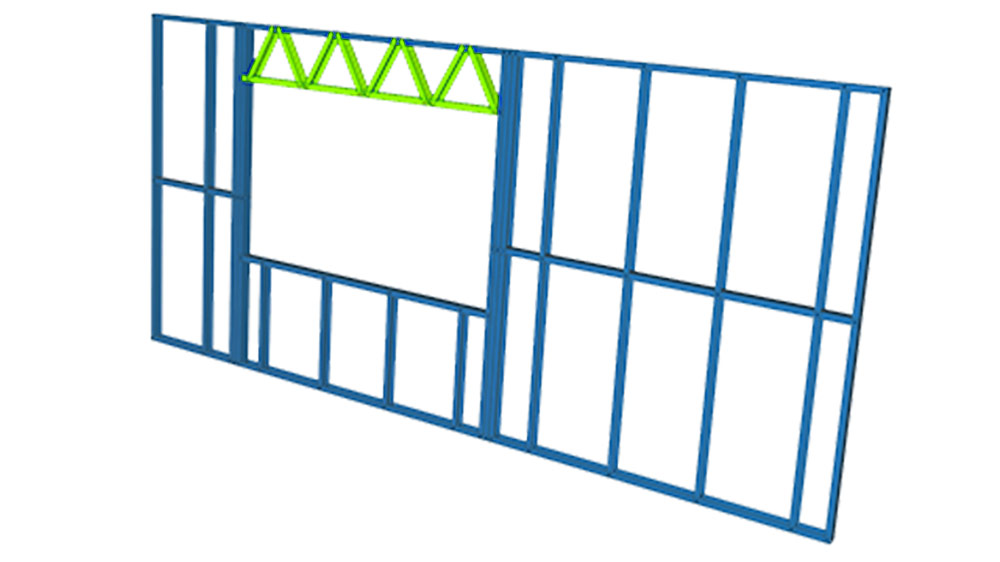

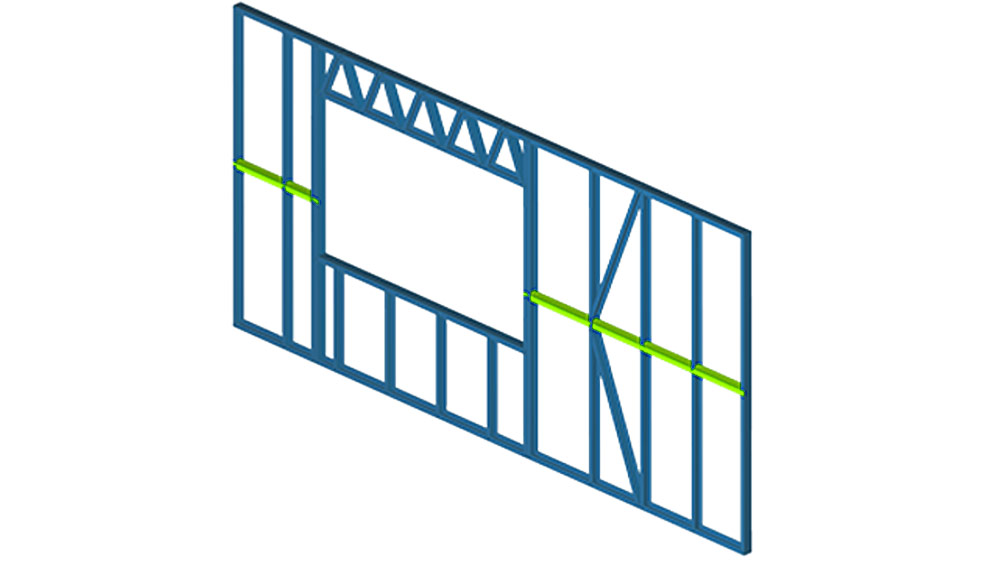

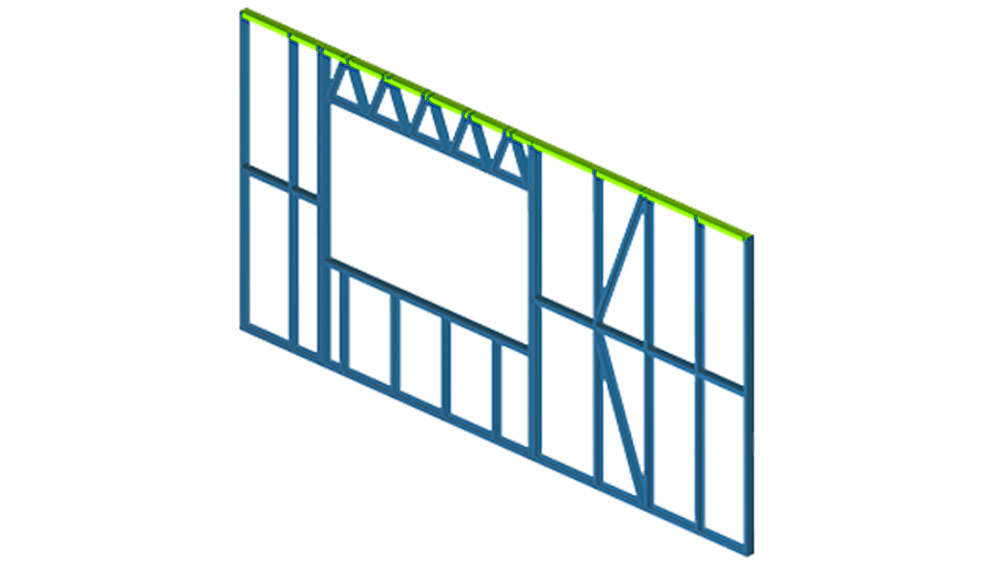

WALL PANELS

BOTTOM PLATES

K-BRACING

JAMB STUDS

LINTELS

NOGGING

TOP PLATES

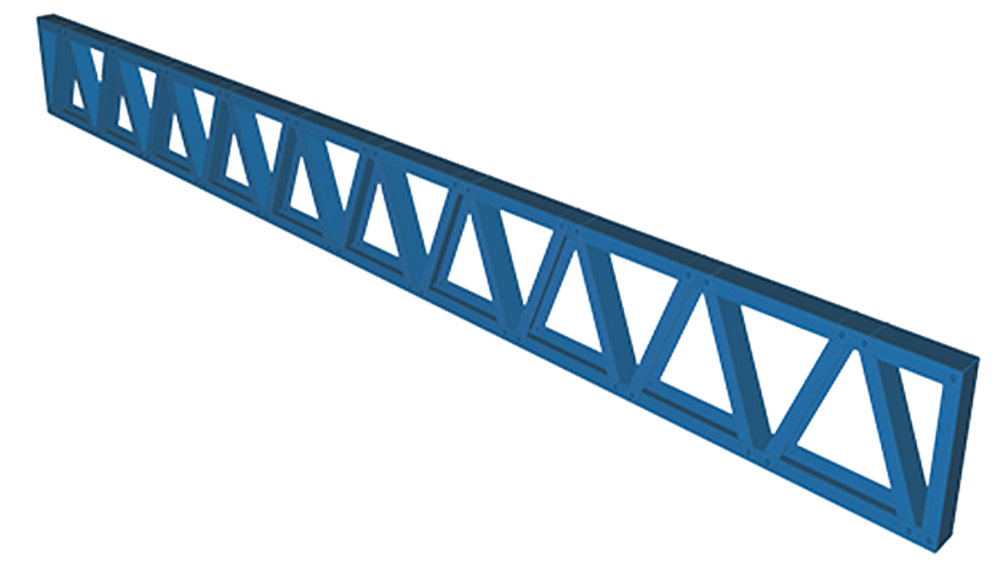

WEBBED FLOOR JOIST

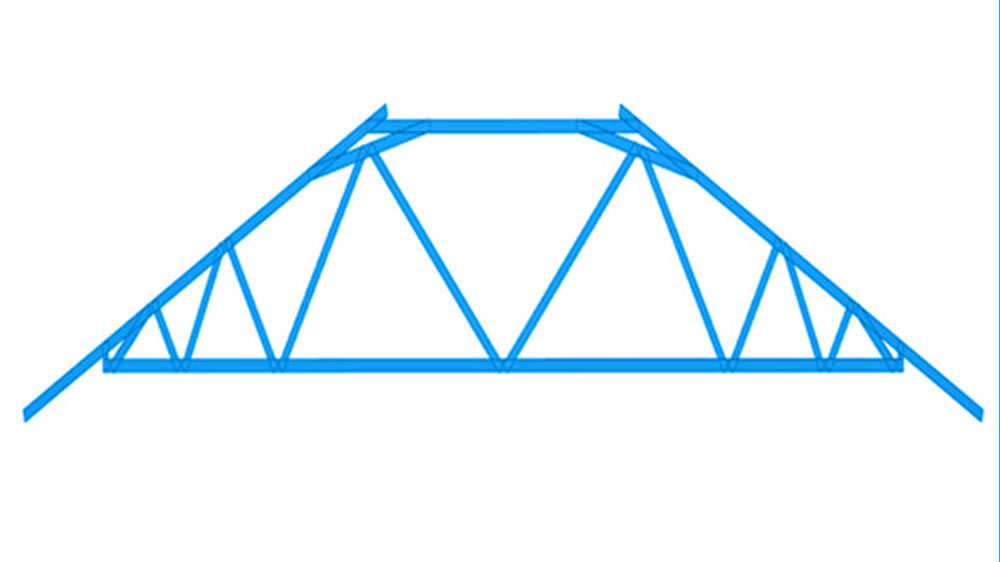

GIRDER TRUSS

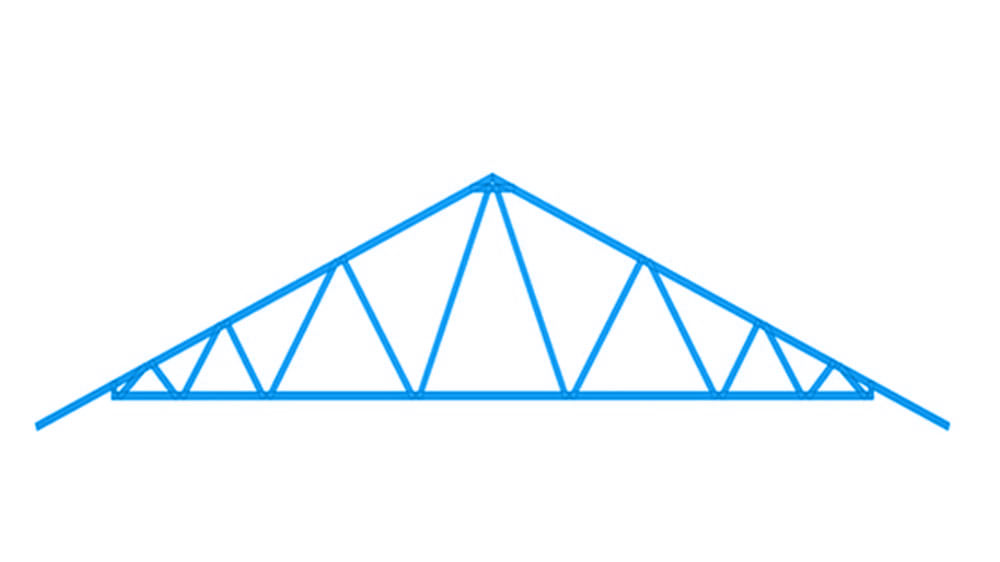

STANDARD TRUSS

TRUNCATED TRUSS

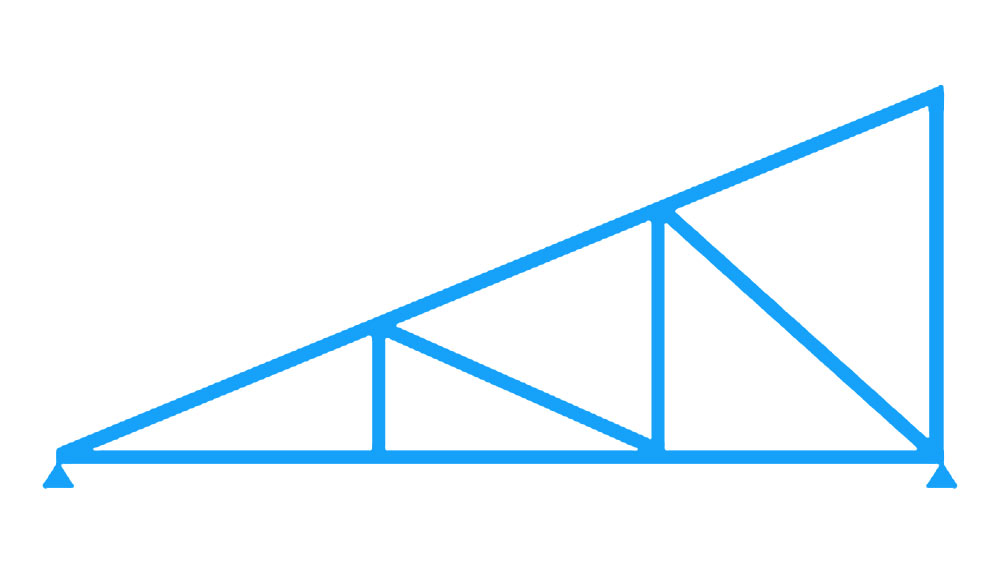

HALF TRUSS

With Cold-Formed Steel wall panels, each level of a structure can be framed out rapidly in a day or two, compared to a week or more with traditional framing.

design of cold-formed

steel structures

Crowder Steel Framing is a design-led process, meaning that the need for skill to construct the building is more in the design stage rather than on-site.

Crowder Steel Framing uses the FrameCad software suite, which integrates design, engineering calculations, structural analysis, detailing, and roll-forming machine control. providing extreme accuracy and efficiency in the construction process, reducing costs of engineering, design, waste, and labor.

Let's Get Started

Complete the form and we'll get back to you promptly.